As trade talks between the US and China heat up again, the “critical dependencies” of the global supply chain in 2025 are once again being exposed to the spotlight. For many buyers who are purchasing industrial or medical oxygen equipment, a grim reality that they have to face is that the supply of core components such as magnetic valves, flow sensors, rare earth-based molecular sieves, etc. is no longer just a matter of price and delivery, but a risky game of policy, region, regulations, and other intertwined variables. This is not only related to whether the equipment can be delivered smoothly, but also related to whether the project itself can be put into operation as scheduled.

So the question is: when “political interference” becomes the norm, chip and rare earth export restrictions have become a reality, oxygen equipment purchasers how to ensure that the supply will not be interrupted? Which supply chains are more stable? Which configurations are potentially risky? Can these risks be mitigated through technology selection and diversification of manufacturing locations? These are the most pressing concerns of global buyers today.

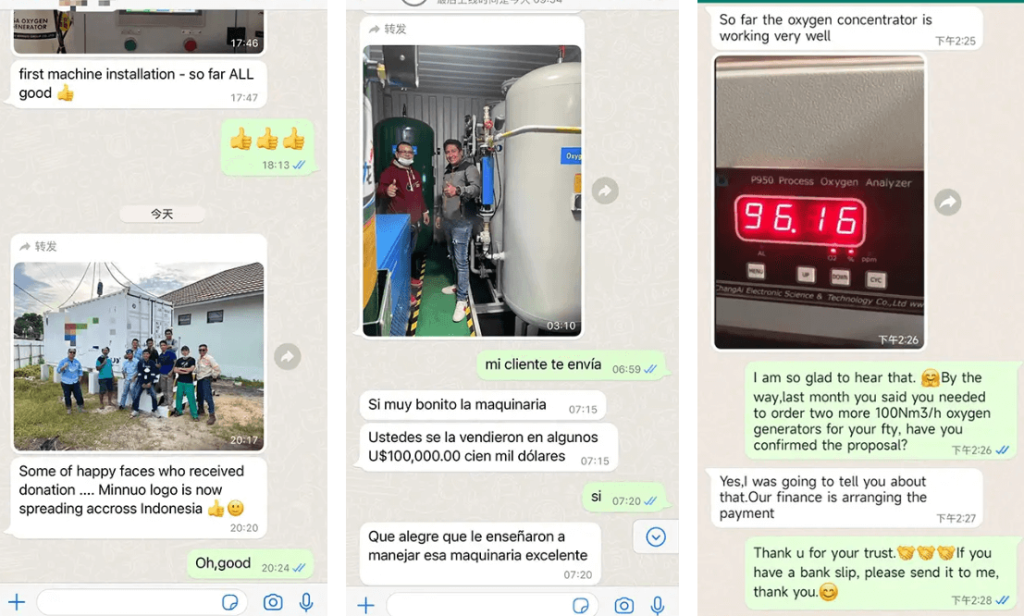

In this article, MINNUO, a PSA Oxygen Systems manufacturer with 20 years of export experience and service in 65 countries, will share our observations and insights into what risks are already occurring, what strategies are working, and which buyers are at the forefront of hedging their bets. This paper will provide a breakdown of the controllable variables in an era of uncertainty and offer practical advice on supply chain stabilization.

Global Hotspot: Rare Earths and Semiconductor Restrictions

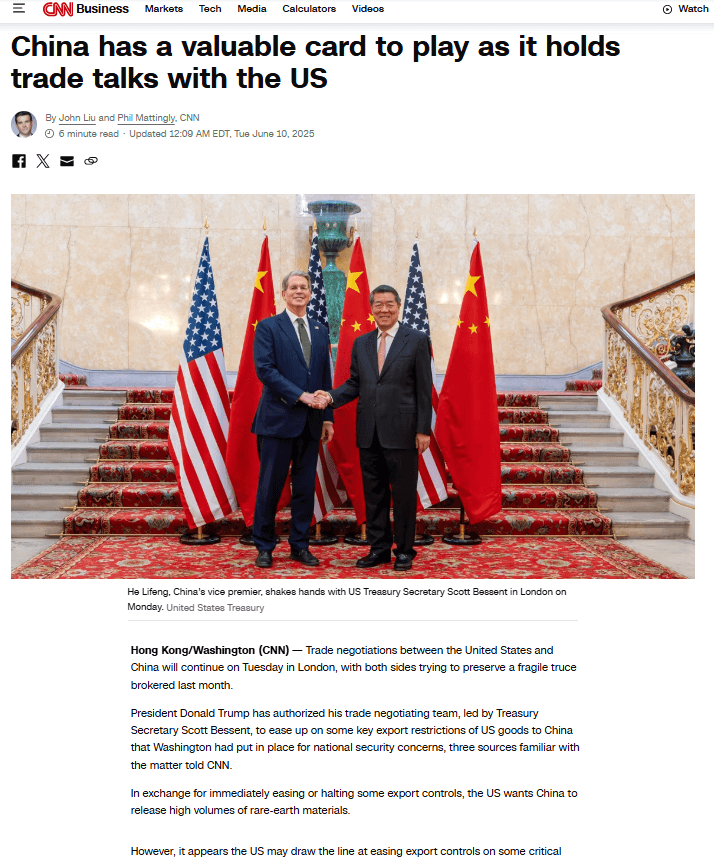

According to a new CNN report, the U.S. government is considering a limited loosening of exports of some mid-range chips in exchange for increased exports of rare earth minerals from China – Rare earths are the “invisible backbone” of virtually all modern industrial equipment, from electric cars to compression systems to smart sensors “invisible skeleton.”

But the problem goes far beyond the smartphone or electric car sector. In the field of industrial oxygen production, rare earths also indirectly determine the “stability” and “maintainability” of oxygen systems. For example, in the PSA oxygen system, rare earth elements are used in the manufacture of key components such as magnetic valves, sensor circuits, and high-precision flow regulators, and the stability of the supply of these components directly affects the operational purity and service life of the entire system.

Why will rare earth restrictions affect the global oxygen industry?

China controls more than 90% of the world’s rare earth refining capacity, even though the raw minerals can be mined in many countries around the world, most of the real “usable material” relies on China’s factories;

Modern oxygen systems are increasingly relying on automation and intelligent modules, which makes the system more reliant on rare-earth related components (e.g., real-time monitoring chips for oxygen concentration);

Medical oxygen systems, laboratory gas sources, and industrial welding scenarios require high gas purity and continuous stability, and any minor fluctuations can trigger false alarms or process interruptions.

Expert Perspective: Robin Xing, Chief China Economist at Morgan Stanley, noted that “China’s strategic control of rare earths has become a strategically binding policy tool. Any industry involved in precision gas applications without a stable supply of rare earth components is at risk of medium to long-term volatility.”

Response advice: what can you do as a buyer?

| Strategic Direction | Suggestions for action |

| Diversify sourcing chain | Cooperate with oxygen equipment manufacturers with non-single supply chain (e.g. CJK+European components) to reduce geographic risks; |

| Review degree of equipment modularity | Select PSA systems with interchangeable components and multi-brand compatibility to avoid being “stuck with a certain model”; |

| Inquire in advance about lead times for rare-earth related parts | Set up a spares inventory system for sensitive components such as solenoid valves, pressure transducers, controllers, and so on; |

| Focus on vendor’s ability to provide localized support globally | For example, MINNUO provides local warehousing and emergency spare parts support in the Middle East/Southeast Asia to ensure delivery continuity. |

| Require multi-market certifications for products (CE + ISO13485) | can cope with cross-border policy fluctuations and unexpected export compliance requirements. |

MINNUO’s Commitment

As a long term export oxygen equipment manufacturer, MINNUO is committed to building a global supply network with high resistance to external shocks, multi-sourcing of components, and fast service response. Our products are designed with:

All key control components support more than two alternative models;

Modular interface design for easy maintenance and localized repair;

Special inventory support program for magnetic valves, molecular sieves, sensors for medical users;

Local agent network covering 50+ countries.

Key Risks for Oxygen Concentrator Buyers

In the current complex and volatile global supply chain, international buyers, hospital engineering companies, and industrial gas users are facing a series of procurement risks arising from trade policies, geopolitical conflicts, and technical barriers. Here’s how these risks can have a substantial impact on your project cycle and equipment stability.

Four Core Risks of Highly Sensitive Components and Technology Dependency

| Risk Type | Typical Performance | Possible Impacts | Risk Signals |

| Rare Earth Export Delays | Limited supply of pressure regulators, magnetic valves, flow sensors | Unstable automatic switchover, increased equipment alarm rate, fluctuating oxygen output | Component lead times >45 days, vendors frequently change original models |

| Semiconductor Restrictions | Delayed supply of chips for oxygen concentration sensing, AI control, or digital instrumentation | Failure of equipment monitoring function to enable remote management | Control panels become less responsive, vendors no longer commit to specific feature versions |

| Escalating Trade Compliance and Export Restrictions | Increased export scrutiny for specific countries or industries leading to delays in customs clearance | Failure of import/export or suspension of deliveries of medical/industrial oxygen generators | Customs documentation requirements become more complex, lead times cannot be locked in |

| Soaring Raw Material Costs | Increased stainless steel prices, surge in cost of core components for gas analyzers | Increase in the cost of purchasing the entire machine, uncontrolled budgets | Quotations become less valid, vendors ask for pre-payment price locks |

Practical advice: How can purchasers “save for a rainy day”?

Choose an equipment supplier with a diversified parts supply system

MINNUO’s oxygen generation system utilizes a combination of key components supplied from China, Korea and Europe to ensure that equipment delivery can be completed on time even if there is a sudden closure of an individual region.

Require modular design to ensure easy replacement

Key components such as magnetic valves, molecular sieve chambers, and sensors have a standardized snap-on design, which supports rapid multi-brand replacement and eliminates the need to return the entire unit to the factory.

Clarify the “chip type” and “country of origin” that the product relies on.

Avoid purchasing monitoring systems based on “U.S.-made control chips”, and recommend the use of embedded logic controllers with strong substitutability. Avoid purchasing surveillance systems based on “U.S.-made control chips”.

Review suppliers for local compliance support documentation

including customs codes, declarations of origin, export licenses, etc., especially for highly sensitive destinations such as the Middle East, Southeast Asia, and Africa.

Prioritize working with brands that can provide regional transit inventory

MINNUO has established forward stocking warehouses in ASEAN and the Middle East, which enable shipments to be made within 48 hours and reduce the risk of waiting.

Strategic solutions: From reactive to flexible

1. Sourcing from brands with proven multinational component chains

At MINNUO, we do not rely on a single source for rare earth sensitive parts. Our supply chain integrates component partners from Europe, Korea and Southeast Asia, ensuring that you get continuous delivery even in times of trade shocks.

2. Choose a system with standardized and interchangeable modules

We designed the PSA oxygen generator with modularity in mind. If a supplier’s solenoid valves are limited, we can switch to another proven brand without delay.

3. Prioritizing in-country assembly and after-sales support

For high-risk countries, we offer containerized PSA oxygen systems that can be assembled locally with standard civilian connections, minimizing customs risk and ensuring continuity of care.

4. proactive monitoring of tariff changes

MINNUO’s international team provides our distributors with monthly updates on new export license changes and bilateral tariffs, so that your projects remain cost predictable.

5. Apply for dual certified products (CE + ISO13485)

This not only ensures regulatory readiness in multiple markets, but also prevents sudden import restrictions due to medical classification mismatches.

Global Overview: Issues for Buyers in the Second Half of 2025

Against the backdrop of AI-led search, tightening trade policies, and accelerated restructuring of the global manufacturing and logistics system, the challenges faced by buyers of oxygen systems in the second half of 2025 are increasingly showing a compound trend of “regional differences + global conduction”.

Regional Trend Observation and Purchasing Suggestion

| Region | Current Challenges | Suggested Purchasing Response Strategies |

| United States | Artificial intelligence chip controls continue to escalate | Select CE/ISO certified equipment and ensure modules meet US FCC, UL, etc. |

| Europe | Higher standards for some embedded control systems, image recognition modules, etc. | Look for equipment configured with non-rare-earth alternative components, |

| Middle East | Tightening of rare earth export audits in China and Europe | and provide “Magnetic Component Declaration of Origin” for customs clearance |

| Southeast Asia | More cautious customs clearance of equipment containing magnetic control components | Select brands with pre-approval mechanisms, |

| Africa | High incidence of customs delays in compressor imports | e.g. modularized equipment + Chinese/Arabic language Compliance Documents |

Extended advice: How can global buyers avoid being “reactive”?

Regularly track policy trends

Subscribe to updates from customs, health authorities and ministries of industry, and combine with international compliance notifications provided by manufacturers (e.g. MINNUO’s Monthly Export Notices)

Confirm the model of “Neutral/Dual Certification” modules with manufacturers in advance

For example, whether the sensors, displays, control chips and driver power supplies have the European and American dual-zone general licenses, to reduce the risk of unilateral embargoes at export destinations. Confirm in advance with the manufacturer whether the “neutral/dual-certification” module models, such as sensors, monitors, control chips and driver power supplies, have the general license of Europe and the United States, so as to reduce the risk of unilateral blockade by the exporting place.

Establish cooperation with brands that support sub-regional shipment.

Priority is given to purchasing equipment that supports “remote debugging + cloud diagnosis.

The equipment can be used in the event of logistics uncertainty or difficulties for after-sales service personnel. Ensure uninterrupted commissioning and maintenance of equipment when logistics are uncertain or after-sales service personnel are difficult to reach on site

What can MINNUO do for you?

Provide regional warehousing + multi-language compliance certificate support (English, French, Arabic, Spanish)

Oxygen generation system supports remote commissioning, AI self-test module, low voltage working mode in remote areas

Provide “Market Situation Dynamic Briefing” to help customers anticipate the trend of tariff, exchange rate, and customs policy changes on a monthly basis

Provide “customized model list by country” to ensure that no additional hardware is required when bidding/exporting. Ensure that no additional hardware adjustments are required when bidding/exporting

Advantage of Minnox: Reliability in uncertain times

Under the background of the international trade situation is full of variables, uncertainty has become the biggest challenge for global buyers. MINNUO understands that the cost of uncertainty in the delivery of equipment is much greater than the price itself, so we always insist on the cornerstones of “Deliverability, Safety and Compliance, and Global Service” to guarantee you worry-free purchasing.

Professional Manufacturing: Global Market Proven Technical Strength

20+ years of experience in exporting oxygen generators to 65 countries and regions

Core products cover a full range of modular PSA oxygen generating systems with flow rates from 3-100 Nm³/h

Products have passed multiple access standards and clinical regulations in China, EU, Middle East, Africa, America, etc.

Rapid Delivery: Modules are standardized, ready to be installed and used.

Standardized component platforms are adopted in large quantities to achieve the shortest production cycle of 7 working days.

All pre-takeover and configuration tests have been completed before the equipment is shipped out of the factory, so there is no need to re-commission the equipment when it arrives at the site.

For special scenarios, such as hospitals, highland projects, and emergency response systems, we support the customization of “quick-assembly all-in-one solutions”.

A full set of compliance documents for bidding and customs clearance in both directions without any worries.

Standard support documents include: IQ/OQ, CE, ISO13485, RoHS, HS Code, Certificate of Origin, DDP Permit Letter

For government projects, international assistance, import compliance filing, etc.

Language versions available upon request (English, French, Spanish, Arabic)

Global support network: wherever there’s a device, there’s a service.

| Region | Services | Response Mechanism |

| China and Southeast Asia | Engineering Spare Parts Warehouse + On-site Training | 48 hours arrival on-site support |

| Middle East and North Africa | Arabic Technical Services, Customized Equipment Certification Assistance | Provide on-site technical support for tenders |

| Europe | French/German Packet Support + UK CE Liaison Service | Remote commissioning + local training certification |

Stability is the most expensive quality

In today’s international environment where “order confirmation ≠ delivery guarantee”, MINNUO always takes “on-time delivery” as the core value. In the era of racing against uncertainty, what we give is not a promise, but an execution.

If you are advancing the project of medical oxygen supply system, industrial gas centralized gas supply station, military field emergency system, welcome to contact us for exclusive solutions.

Final Thought: Build Your Resilience Before Trade Tensions Increase

The current trade game between China and the US has not yet come to an end, but for global gas equipment buyers, “waiting for the situation to clear up” is no longer a safe option. For buyers with real risk defense, they often complete the diversified layout of the supply chain and the alternative testing of core modules long before the policy change. Whether you are serving a war hospital in the Middle East, a remote clinic in the mountains of Africa, or a high-end welding factory in Europe and the United States, stable supply is never a matter of “after procurement”, but a decision made “at the beginning of the strategy”.

MINNUO, as a PSA oxygen equipment manufacturer with global service capability, has always believed that in times of uncertainty, a reliable partner is the real “certainty” for buyers. We not only provide equipment, but also solutions to cope with global policy changes – from export qualification, delivery time, spare parts substitution to multi-region transshipment warehouse support, to build a truly “resilient” oxygen supply program for global buyers.

If you are looking for a partner that can help you maintain oxygen security continuity in a volatile market, please contact MINNUO.

Layout now is not to save for a rainy day, but to take the initiative to win in the game of cost, efficiency and risk.

sales2:+86 17506119168

sales2:+86 17506119168