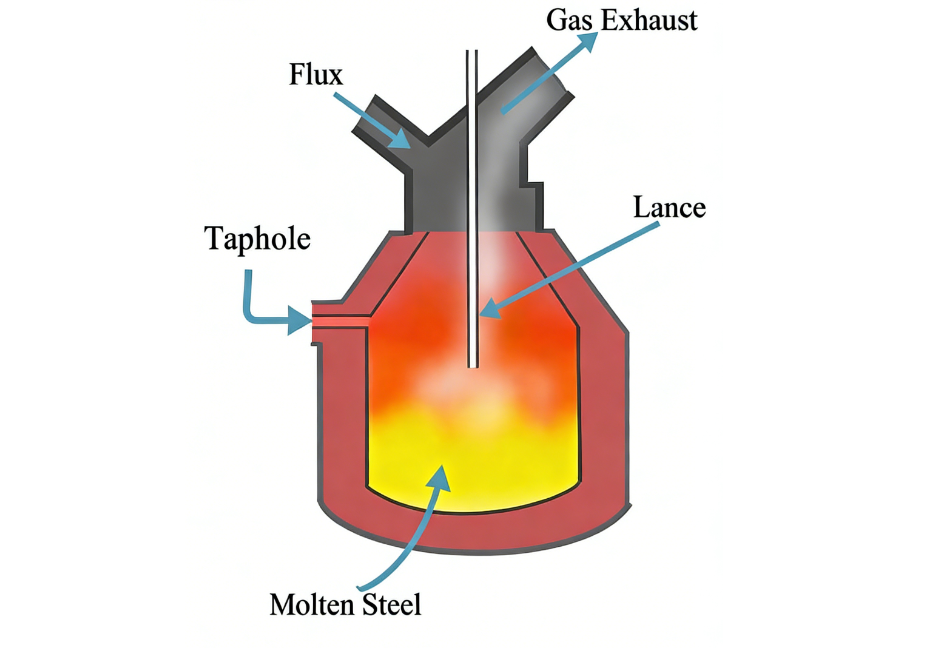

The Role of Oxygen in Electric Arc Furnace (EAF) Steelmaking: Efficiency and Quality Benefits

In the fiercely competitive landscape of modern steelmaking, the Electric Arc Furnace (EAF) has emerged as a champion of efficiency and sustainability, primarily recycling scrap metal into new steel. However, the true secret to its profitability lies not just in the massive electrical energy supplied by its electrodes, but in the strategic use of a […]

Minnuo Small-Scale Liquid Nitrogen Generator | Empowering Efficient Scientific Research in Laboratories with Dual Assurance of Safety and Convenience

In the research scenarios of scientific laboratories, the precise supply, stable output and safe control of liquid nitrogen directly determine the efficiency of core work such as biological sample preservation, low-temperature experiments and superconducting material research, as well as the reliability of research results. Traditional liquid nitrogen relies on external procurement and long-distance transportation, which […]

How is Nitrogen Gas Used in Enhanced Oil Recovery and Well Services?

For the global oil and gas industry, the greatest challenges often lie not in finding new fields, but in maximizing what’s already been discovered. How do you recover more oil from a mature reservoir after primary production declines? How do you perform complex, hazardous well interventions with absolute safety? The answer to both questions increasingly […]

The Optimal Choice for Livestock Sperm Storage! Jiangsu Minnuo Liquid Nitrogen Machine, Boosting Aquaculture Efficiency

In large-scale, modern livestock and poultry breeding, the storage quality of breeding stock sperm directly determines breed improvement, reproductive efficiency and breeding profits. High-quality breeding stock sperm is scarce and precious, and how to achieve long-term, safe storage while avoiding activity loss, contamination and deterioration has become a core pain point for numerous farms and […]

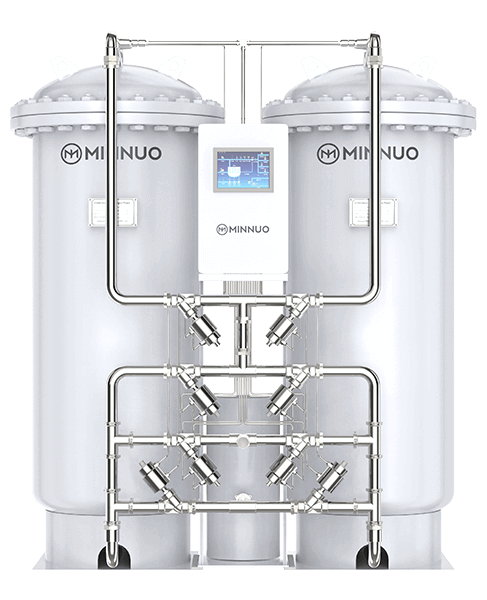

What is Pressure Swing Adsorption (PSA)? The Technology Behind N2 & O2 Generators

Air is a uniform mixture of gases—until you need just one of them. The ability to pluck high-purity nitrogen or oxygen from the atmosphere on demand is a cornerstone of modern industry, enabling everything from preservative-free food packaging to life-saving medical oxygen. At the heart of this capability lies a remarkably elegant and efficient physical […]

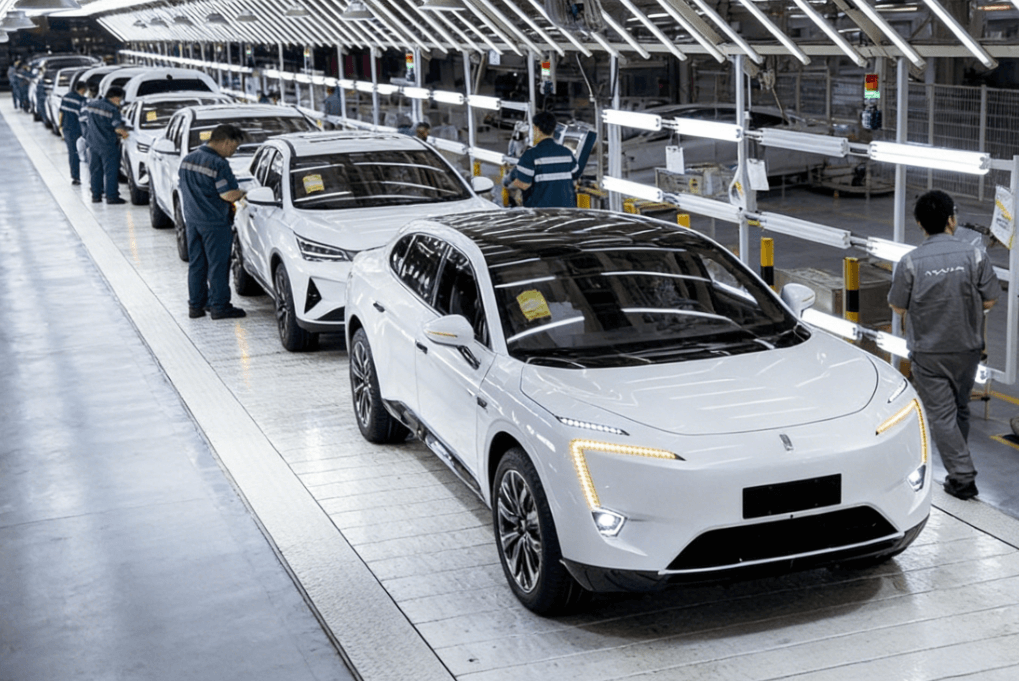

High-Purity Nitrogen Guards Green Mobility: Jiangsu Minnuo Nitrogen Generators, the Quality Core of the New Energy Vehicle Industry

Introduction: Who Guards the “Invisible Safety Line” of the Automotive Industry Amid the New Energy Wave? As new energy vehicles become the core driving force of the global transportation revolution, technological breakthroughs in every link, from battery safety to vehicle quality, have captured the attention of the entire industry. What is little known is that […]

How Do Industrial Liquid Nitrogen Generators Work? A Complete Process Guide

Liquid nitrogen (LN₂) is the lifeblood of modern industry, enabling everything from the flash-freezing of gourmet meals to the cryopreservation of biological samples and the shrink-fitting of aerospace components. For facilities with large, consistent demand, the traditional model of purchasing LN₂ from external suppliers—with its volatile pricing, logistical complexities, and delivery dependencies—becomes a significant operational […]

PSA Oxygen Generator Process Flow and Full Component Maintenance Guide

PSA oxygen generators are the core equipment for on-site oxygen production in industrial manufacturing, medical supply, and aquaculture industries, relying on pressure swing adsorption (PSA) technology to achieve efficient oxygen-nitrogen separation from ambient air. This guide details the full PSA oxygen generator process flow, step-by-step maintenance requirements for all key components, and universal maintenance principles. […]

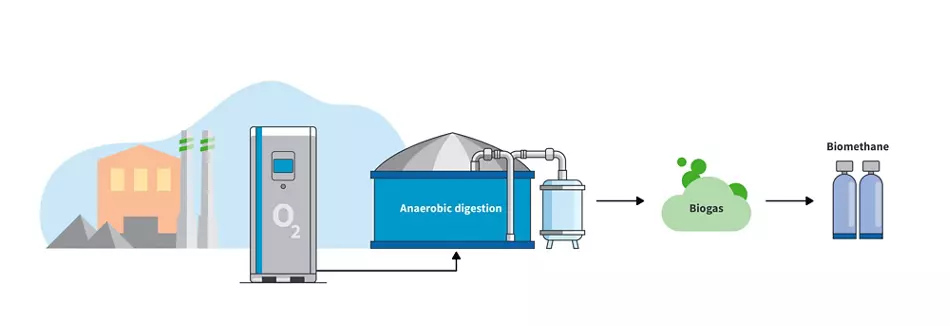

How Can a PSA Oxygen Generator Upgrade Biogas to Biomethane Efficiently?

As the world shifts towards renewable energy, biogas—produced from anaerobic digestion of organic waste—has emerged as a key player. However, raw biogas contains 25-45% CO₂ and trace contaminants like hydrogen sulfide (H₂S), which limit its energy value and pipeline compatibility. Upgrading it to high-purity biomethane (or Renewable Natural Gas – RNG) requires removing these impurities. […]

Application of Nitrogen Generators in Natural Gas Pipeline Purging and Customer Usage Recommendations

I. Core Applications and Technical Principles of Nitrogen Generators in Natural Gas Pipeline Purging (1) Core Application Scenarios Natural gas pipelines must be purged with inert nitrogen generated by nitrogen generators at three critical nodes: prior to commissioning of new pipelines, after maintenance and renovation, and before reactivation after long-term shutdown. The core objectives are […]

sales2:+86 17506119168

sales2:+86 17506119168