Green Steel Transformation: Strategic Demand Analysis for Oxygen and Nitrogen Generators in the Indonesian Steel Industry

Oxygen and nitrogen generators are no longer mere auxiliary production equipment; they are strategic assets for Indonesian steel enterprises to hedge against carbon tax risks, reduce coke ratios, and enhance core competitiveness.

On-Site Nitrogen Generator: 5 Costly Mistakes to Avoid When Buying (And How to Get It Right)

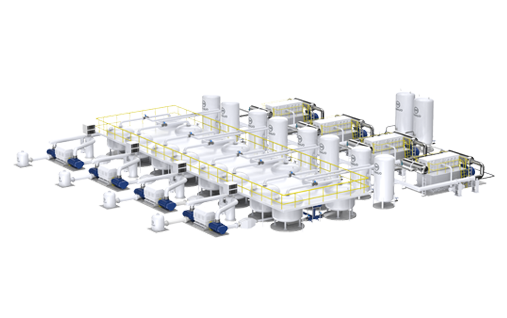

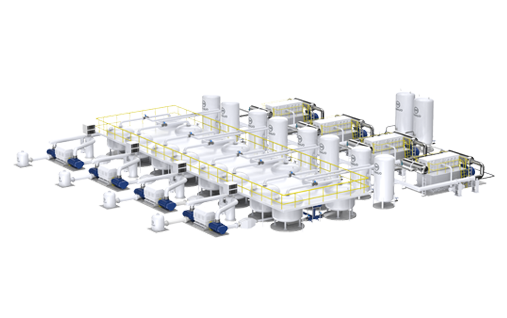

Investing in an on-site nitrogen generator is a strategic decision to gain control, predictability, and long-term cost savings. However, the path to a successful project is fraught with technical and commercial pitfalls that can transform this capital investment into a decade-long source of operational headaches and financial underperformance. The difference between a thriving asset and […]

How Indonesian Coal Power Plant Practitioners Can Leverage Oxygen & Nitrogen Generation Technology for Emission Reduction and Safety

How can Indonesian coal power plants respond to emission reduction pressures from the ‘Toxic Twenty’ report? This article provides an in-depth analysis of leveraging on-site PSA oxygen and nitrogen generation technology to optimize FGD desulfurization efficiency and prevent spontaneous coal combustion, helping plants achieve a win-win for health and economy while enhancing operational safety.

Why Oxygen Generators are the “Immediate Solution” for Indonesia’s Steel Decarbonization

As production and technical leaders in Indonesian steel plants, we must recognize that before Green Hydrogen steelmaking reaches large-scale commercialization, improving the energy efficiency of existing Blast Furnaces (BF) and Electric Arc Furnaces (EAF) through Oxygen Enrichment is the most pragmatic and cost-effective decarbonization path.

Jiangsu Minnuo Liquid Nitrogen Machine: High Efficiency, Energy Saving and Low Noise, Empowering Stable Production in Multiple Fields

In fields with growing demand for liquid nitrogen such as medical treatment, food, electronics, and biological research, the performance of liquid nitrogen machines directly affects production efficiency, operating costs, and working environments. As a professional manufacturer with over 30 years of experience in air separation and pressure swing adsorption (PSA) technology, Jiangsu Minnuo has created […]

PSA, VPSA vs. Cryogenic ASU Field Comparison: Selection Guide for the Indonesian Steel Industry Based on the CELIOS 2025 Report

A strategic guide for the Indonesian steel industry comparing PSA, VPSA, and Cryogenic oxygen technologies. Based on the CELIOS 2025 report, it highlights why VPSA technology is the optimal choice for mid-sized mills and RKEF plants to lower energy costs and meet EU-CBAM carbon standards in a tropical, archipelagic climate.

The Silent Killer of Your Nitrogen Generator: It’s Not the Sieve, It’s Your Air

You’ve invested in a state-of-the-art Pressure Swing Adsorption (PSA) nitrogen or oxygen generator. You follow the maintenance schedule, yet purity declines, energy use creeps up, and you face an expensive molecular sieve change years ahead of schedule. The instinct is to blame the generator or the sieve itself. But in the vast majority of cases, […]

PSA, VPSA, or Cryogenic ASU? A “Guide” to Oxygen Plant Selection for Indonesian Steel Mills

Comprehensive guide on choosing Oxygen Plants (VPSA vs. Cryogenic) for Indonesian steel mills. Compare OPEX, energy savings, and logistics challenges in Indonesia’s tropical climate.

Limited Space in Small Workshops? Compact Screw Air Compressors Save 30% Floor Space Without Sacrificing Air Output Efficiency

Introduction: The Space Dilemma Facing Small Workshops For small workshops across Europe, North America, Southeast Asia, and other regions, space is more than just a commodity—it’s a critical constraint that directly impacts productivity, operational flexibility, and profitability. Whether you run a boutique woodworking studio in Germany, a precision metalworking shop in the U.S., an electronics […]

Industry Insider: A Reform Guide for the Indonesian Steel Industry Amid the CBAM Wave

Today, I’m not talking about hydrogen metallurgy, which is still a decade away. Let’s talk about something deployable now—Oxygen Enrichment Technology. This is the most practical means available to achieve a 5-10% emission reduction and significantly lower coke costs without dismantling furnaces or halting production.

sales2:+86 17506119168

sales2:+86 17506119168